Porous PEEK™ Technology

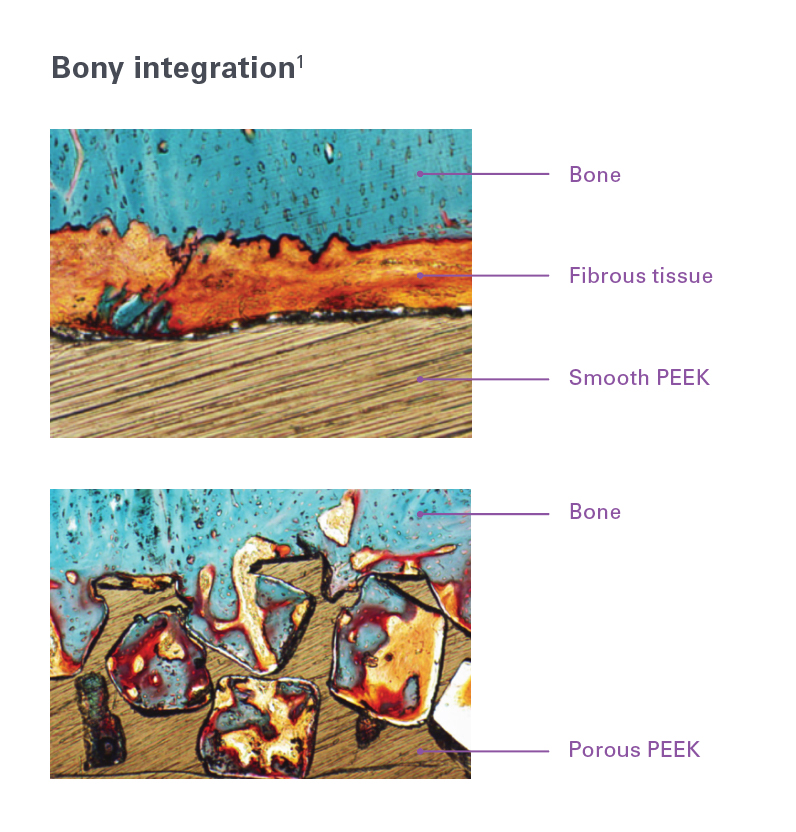

Manufactured through a proprietary extrusion process, the first-of-its-kind porous architecture is designed to promote bone in-growth1 while maintaining the biomechanical1 and imaging properties of PEEK.

Manufactured through a proprietary extrusion process, the first-of-its-kind porous architecture is designed to promote bone in-growth1 while maintaining the biomechanical1 and imaging properties of PEEK.

Adhering to the three core principles of Advanced Materials Science—Surface, Structure, and Imaging—NuVasive has pioneered design and manufacturing methods that combine the inherent benefits of porosity with the advantageous material properties of PEEK to create implants intelligently designed for fusion.

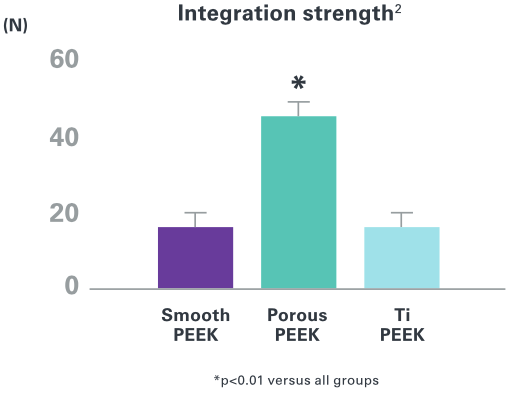

Interconnected porous PEEK scaffold supports strong mechanical interlock through bone in-growth in preclinical animal models. 1-2

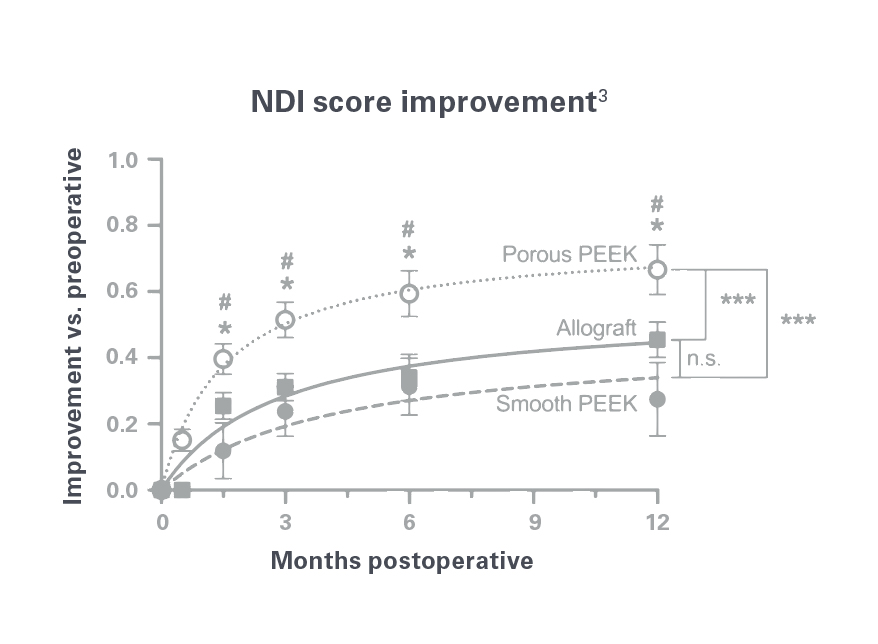

Significant improvements in clinical outcomes reported with porous PEEK vs. smooth PEEK and structural allograft in anterior cervical discectomy and fusion as early as 6 weeks.3

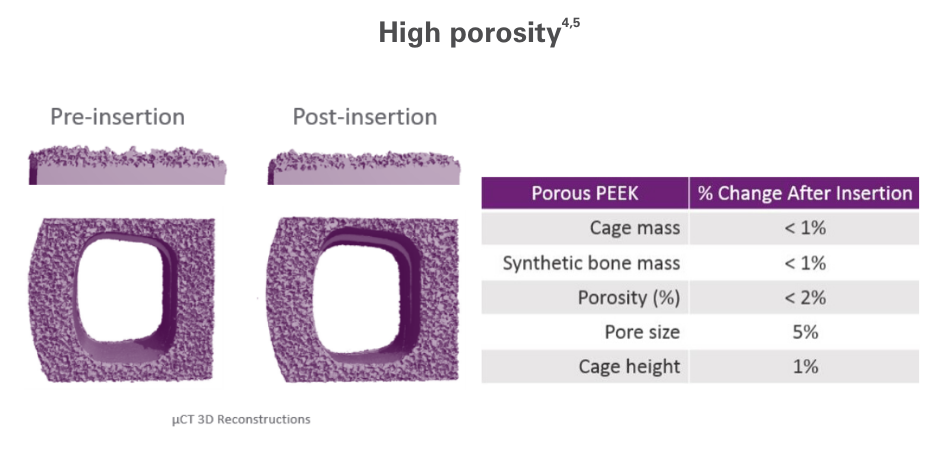

Porous PEEK maintains high porosity under conditions that replicate anatomic loading and resists abrasion damage and delamination under impacted insertion.4,5

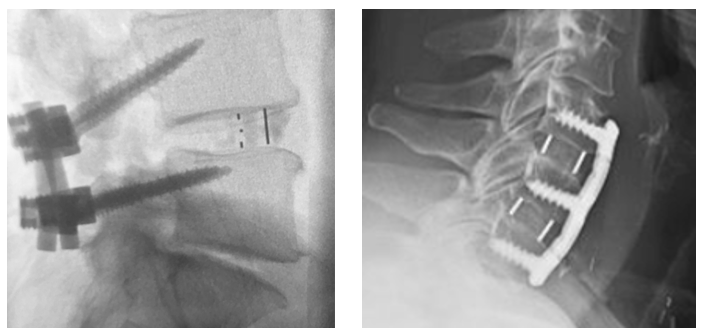

Created with imaging in mind, Porous PEEK leverages the radiolucent properties of PEEK to enable radiographic visualization on a variety of imaging modalities.

This provides surgeons with the ability to assess placement of the implant intraoperatively and confirm fusion postoperatively.

For important product safety information on each of the implants in the Porous PEEK portfolio, including, but not limited to, indications for use, contraindications, warnings, precautions, and potential adverse effects, please see the product specific Instructions for Use which can be found at nuvasive.com/eifu.

1. Evans NT, Torstrick FB, Lee CS, et al. High-strength, surface-porous polyether-ether-ketone for load-bearing orthopedic implants. Acta Biomater 2015;13:159-67.

2. Hill CP and Strenge KB. Early clinical outcomes comparing porous PEEK, smooth PEEK, and structural allograft interbody devices for anterior cervical discectomy and fusion. J Spine Neurosurg 2019;8(1):1-7i.

3. Torstrick FB, Lin ASP, Potter D, et al. Porous PEEK improves the bone-implant interface compared to plasma-sprayed titanium coating on PEEK. Biomaterials 2018;185:106-16.

4. Cheng A, Cohen DJ, Boyan BD, et al. Laser-sintered constructs with bio-inspired porosity and surface micro/nano-roughness enhance mesenchymal stem cell differentiation and matrix mineralization in vitro. Calcif Tissue Int 2016;99:625-37.

5. Evans NT, Torstrick FB, Lee CS, et al. High strength surface-porous polyether-ether-ketone for load bearing applications. Acta Biomater 2015;13:159-67.